First Health Care Device Powered by Body Heat Made Possible with Liquid-based Metals

Researchers address battery-life concerns with a new material system that can power a pulse oximeter with body heat alone.

Media Inquiries

In the age of ever-present technology, dead batteries are a common hindrance. But for those relying on a wearable health care device to monitor glucose, reduce tremors or even track heart function, taking time to recharge can pose a big risk.

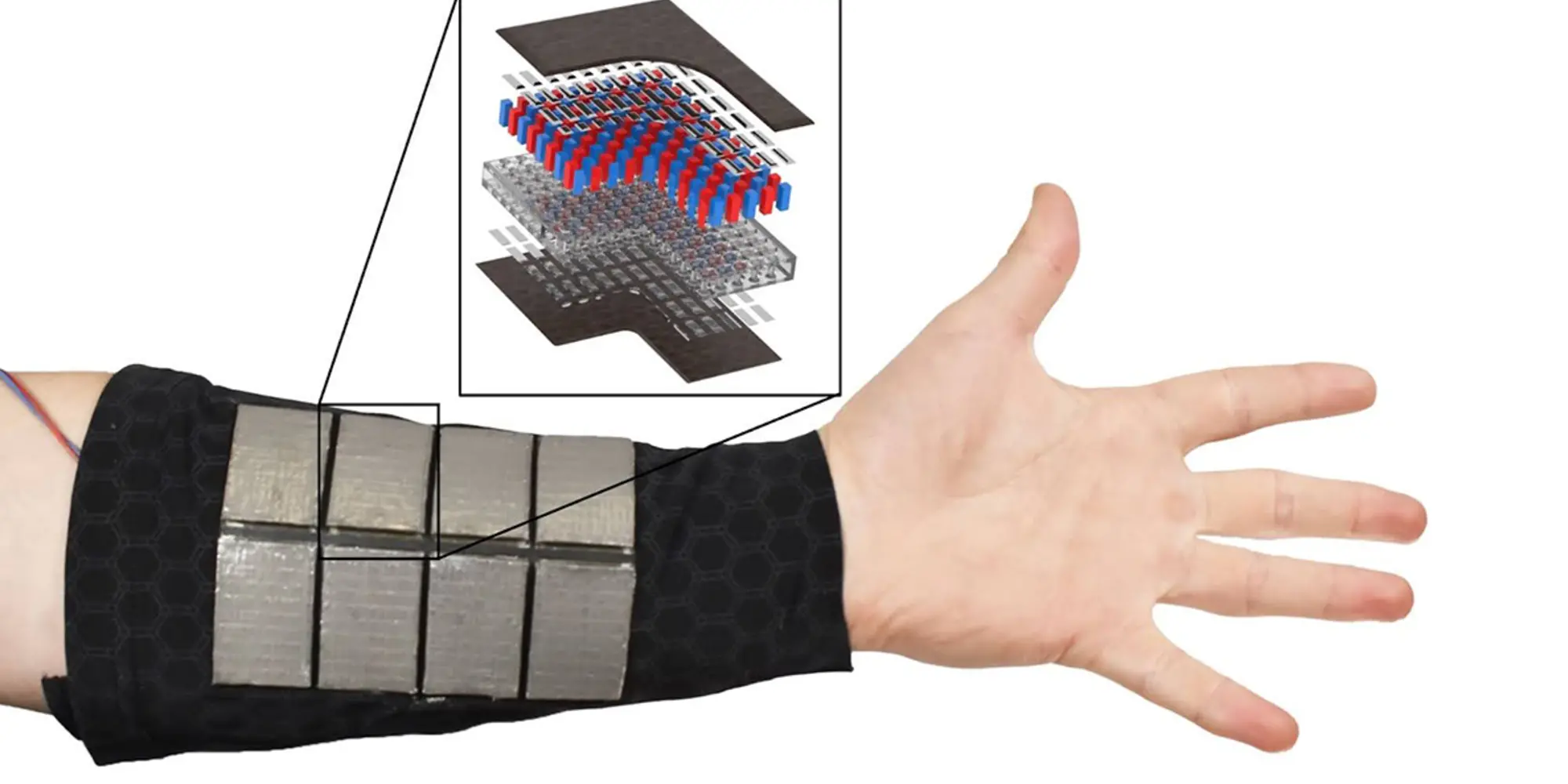

For the first time, researchers in Carnegie Mellon University’s Department of Mechanical Engineering(opens in new window) have shown that a health care device can be powered using body heat alone. By combining a pulse oximetry sensor with a flexible, stretchable, wearable thermoelectric energy generator composed of liquid metal, semiconductors and 3D printed rubber, the team has introduced a promising way to address battery life concerns.

“This is the first step toward battery-free wearable electronics,” said Mason Zadan, Ph.D. candidate and first author of the research published in Advanced Functional Materials(opens in new window).

The system, designed to achieve high mechanical and thermoelectric performance with seamless materials integration, features advancements in soft-materials, TEG array design, low energy circuit board design and onboard power management.

“Compared to our past research, this design improves power density by roughly 40 times or 4,000%. The liquid metal epoxy composite enhances thermal conductivity between the thermoelectric component and the device’s point of contact on the body,” explained Carmel Majidi(opens in new window), professor of mechanical engineering and director of the Soft Machines Laboratory(opens in new window).

To test its voltage output, the device was worn on a participant’s chest and wrist at rest and in motion.

“We saw greater output while the device was on the participant’s wrist and while they were in motion,” Zadan said. “As the participant moves, one side of the device is cooled by the increase in airflow, and the other is heated from the rise in body temperature. Walking and running created an ideal temperature differential.”

Moving forward, Dinesh K. Patel(opens in new window), a research scientist on the team, is eager to work on improving electrical performance and explore how to additively manufacture the device. “We want to move it from a proof-of-concept into a product people can start using.”

This research was done in collaboration with Arieca Inc., the University of Washington and Seoul National University.